Aerospace engine case inspection system

Industry

Aerospace

Challenge

Ensuring the integrity of engine case connections between the hot and cold side engine halves of service parts.

Results

FOERSTER developed a comprehensive test solution, as the System meticulously processes over 100 hole masks across multiple zones.

Key Products

STATOGRAPH, STATOVISION, VISION SENSORS

Back to the Landingpage Customized Solutions for components testing

The Challenge

Ensuring the integrity of the engine case connection between the hot and cold side engine halves is paramount. This component features numerous holes, grooves, and hard-to-reach areas, with part diameters ranging from 0.5 meters to over 1 meter. The inspection focuses on detecting small cracks, predominantly originating around the hole areas and some flat surfaces. It is important to note that the parts undergoing this rigorous inspection are service parts, not new OEM production parts.

The FOERSTER Solution

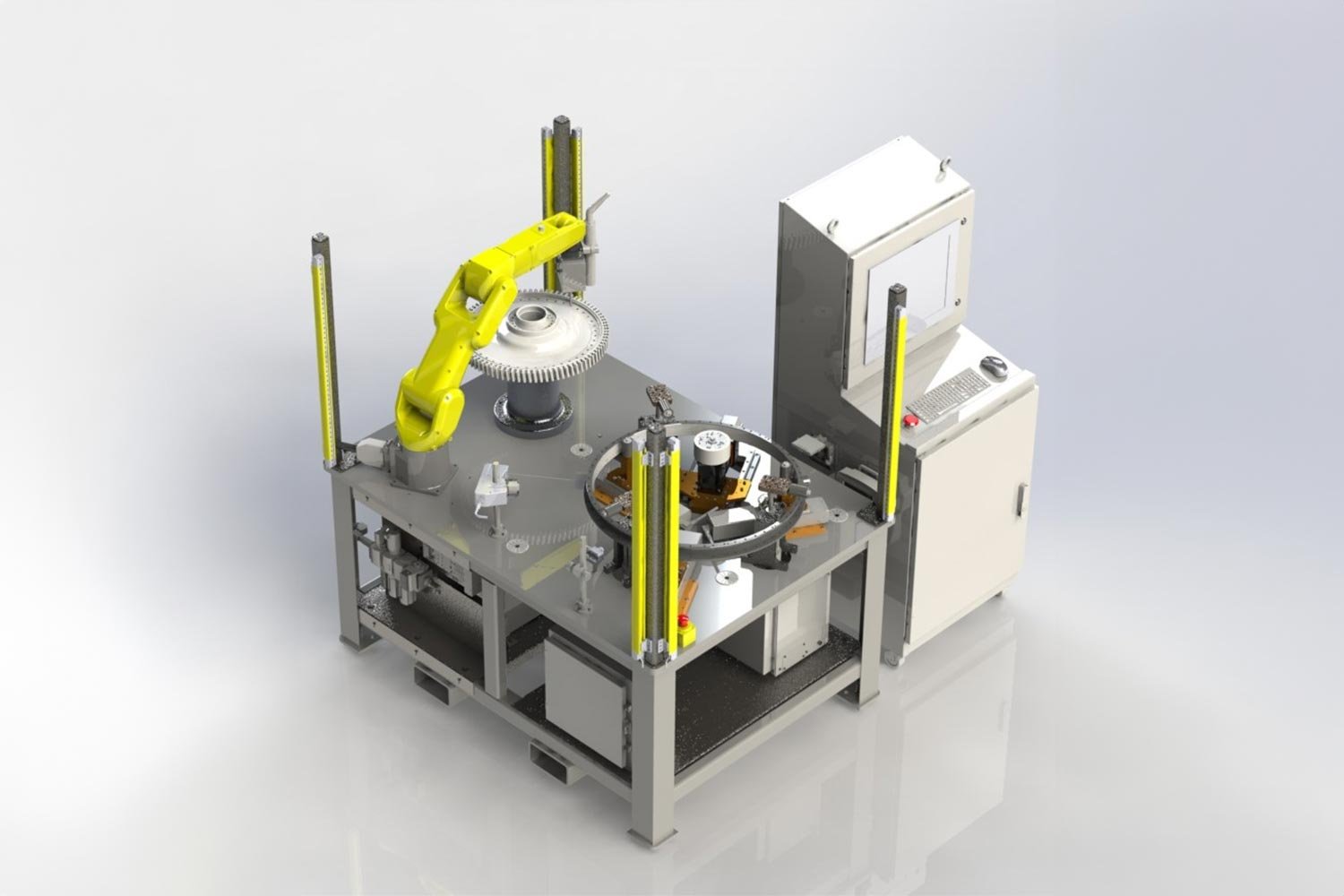

FOERSTER developed and implemented a comprehensive eddy current testing solution for engine case components. This system seamlessly accommodates numerous engine family part diameters by simply inputting the part number into the operator interface. The innovative open table design facilitates effortless loading and unloading of parts using an overhead crane. Each component undergoes thorough test zone analysis, with 2D C-scan imaging provided via STATOVISION software. Additionally, all part data is meticulously stored, ensuring traceability and enabling future root cause analysis.

Specalties worth mentioning

The masking of thru-holes and threaded holes enables the eddy current test to inspect areas very close to hole edges, a challenge previously known as the "edge effect." This advancement is made possible by the STATOVISION software from FOERSTER. Additionally, robot probe scanning ensures precise profiling movements and necessary scan overlap. The Keyence optical system checks for out-of-round conditions during the initial part rotation to prevent any potential damage to the eddy current probe.

Results

The aforementioned testing solution is comprehensive, as the STATOVISION PC meticulously processes over 100 hole masks across multiple zones. The objective is to complete the engine case inspection within an hour.

Back to the Landingpage Customized Solutions for components testing