Cylindrical rod inspection system

Industry

Industrial manufacturing

Challenge

To inspect cylindrical metal rods for surface defects.

Results

Our inspection system tests cylindrical metal rods for surface defects, performs magneto-induction testing, and handles dimensional gauging and feature recognition, all in one efficient solution.

Key Products

STATOGRAPH CM/CM+, MAGNATEST D/TCL

Back to the Landingpage Customized Solutions for components testing

The Challenge

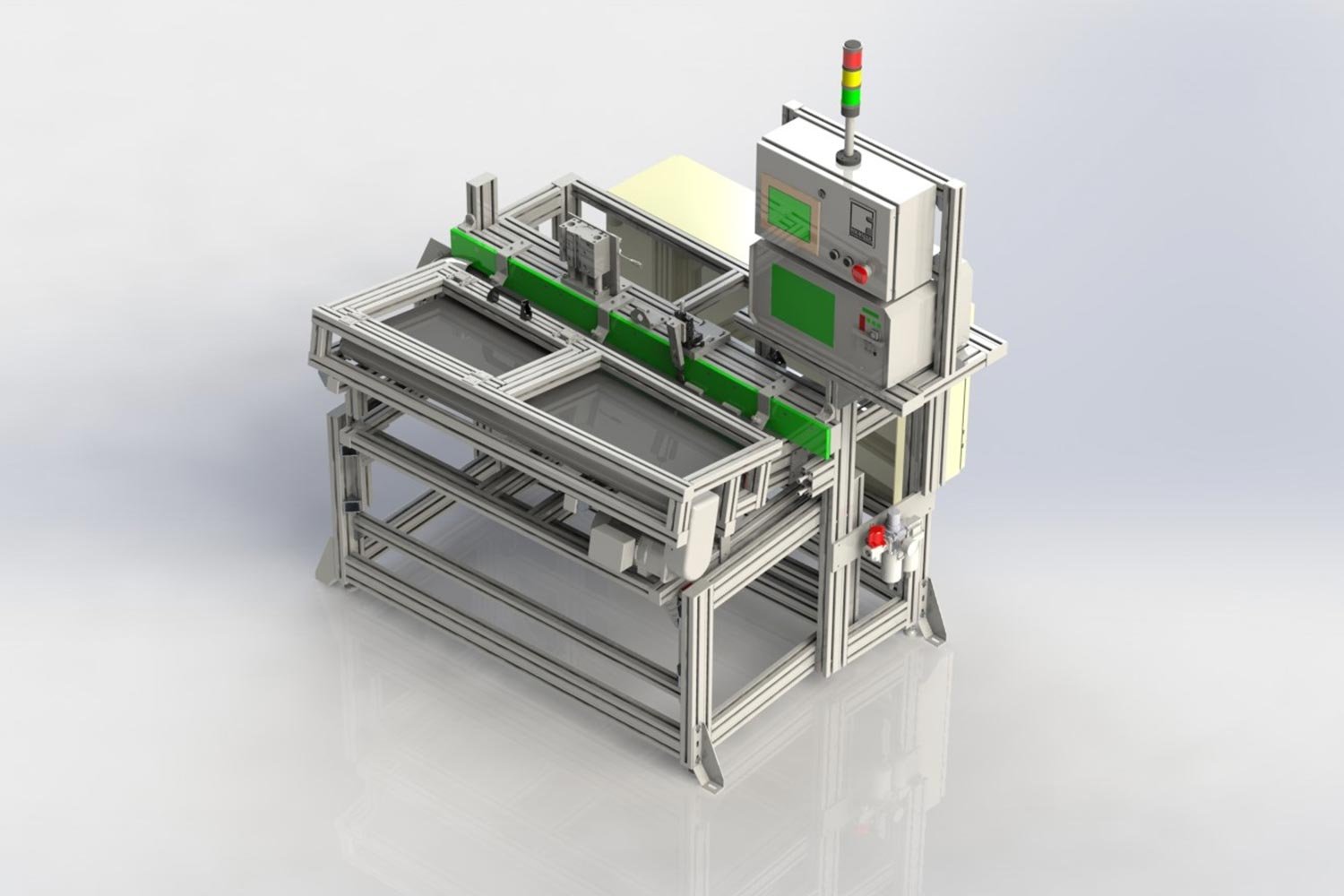

Our quality control inspection system is designed for the comprehensive testing of cylindrical metal products, identifying surface defects such as cracks, porosity, and lapping imperfections. Additionally, it performs magneto-induction testing for heat treatment, case depth, and microstructure analysis, as well as dimensional gauging and feature recognition for critical components. This multi-purpose system seamlessly integrates all these capabilities into one efficient solution.

The FOERSTER Solution

This solution serves as a cost-efficient alternative to the ROTOPUSH system of FOERSTER, providing a comprehensive testing approach for cylindrical products such as shock absorber/strut bars and roller bearing components.

Specalties worth mentioning

The system includes an auto-adjust feature for the STATOGRAPH probe, which automatically calibrates for diameter changes via the user-friendly "recipe" interface. Additionally, a conveyor section can be integrated at the front end for dimensional gauging, as successfully implemented with Aeroel equipment, enabling efficient sorting of parts with EC rejects. A conveyor section for the MAGNATEST sorting gate can also be added, and the system is designed to accommodate additional part diameters and lengths through the user interface, ensuring future adaptability.

Results

The system is designed to detect defects with a minimum specification of 100 microns in depth and width. Typically, the minimum detectable flaw length is 5 mm, though it can be smaller depending on the material and surface finish, with some examples reaching 75 microns. Due to the part trigger type and system limitations, the untested ends are slightly larger compared to the ROTOPUSH system. Additionally, vibrations within the rotating belt and part movement may affect filter settings and reduce the signal-to-noise ratio for certain applications. The system is capable of scanning parts at a speed of up to 125 mm/sec, depending on the length of the flaw.

Back to the Landingpage Customized Solutions for components testing