Upgrade Your Surface Crack Detection with the CIRCOFLUX DA

A fully integrated ACMFL system engineered for faster inspections, sharper flaw detection, and lower long-term operating costs.

A Fully Integrated Flaw Detection System Built for Modern Steel Manufacturing

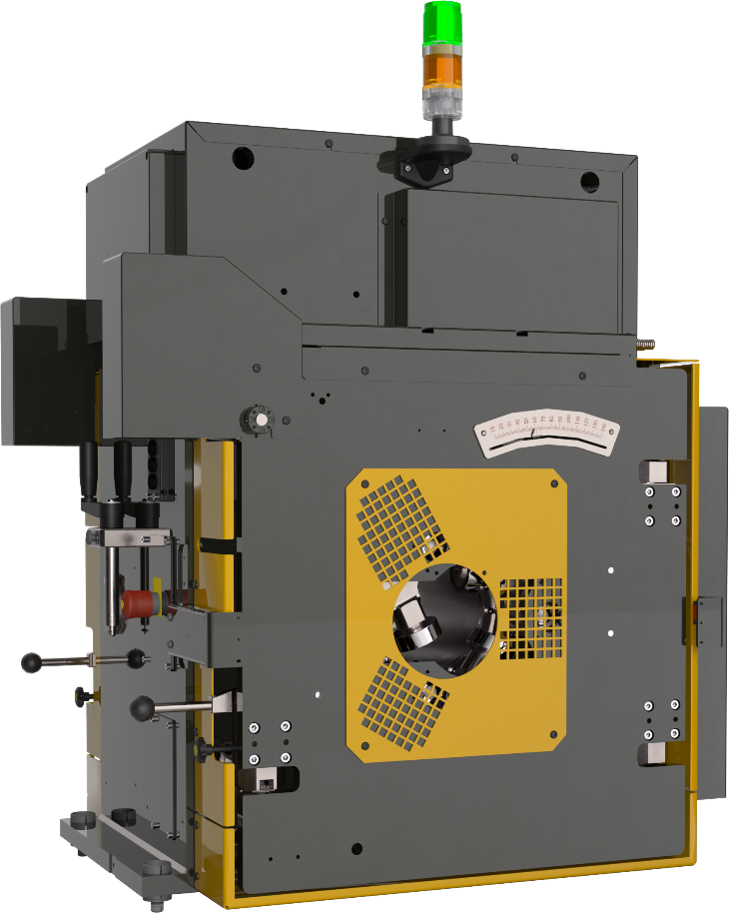

The CIRCOFLUX DA is FOERSTER’s most advanced AC magnetic flux leakage (ACMFL) system, purpose-built for surface crack detection in hot-rolled and black bar steel. Designed to meet the demands of high-throughput production and quality requirements, it combines in-house sensor design, C-Scan visualization, and a low-maintenance inductive architecture in a seamless, turnkey solution.

Whether you are upgrading from legacy equipment or building a new line, the CIRCOFLUX DA delivers high flaw sensitivity, shorter untested ends, and faster test speeds to help quality teams improve yield, reduce scrap, and lower long-term operating costs.

A Solution That Delivers at Every Level

From day-to-day operations to long-term strategic planning, the CIRCOFLUX DA provides measurable improvements across your entire operation. From the production floor to executive strategy, this system solves your biggest inspection challenges and delivers measurable results at every level.

Operators / NDT Techs

NDT & Quality Engineers

Production Managers

Purchasing / Legacy Users

Executives / C-Suite

Maintenance & Reliability

Engineered for Black Bar and Hot-Rolled Steel Inspection

Explore our product infographic to learn more about the CIRCOFLUX DA. Share it with your team.

.png?width=1920&height=1080&name=HS%20Blog%20-%20Large%20Hero%20Image%20(1).png)