Redefining Mobile Eddy Current Testing

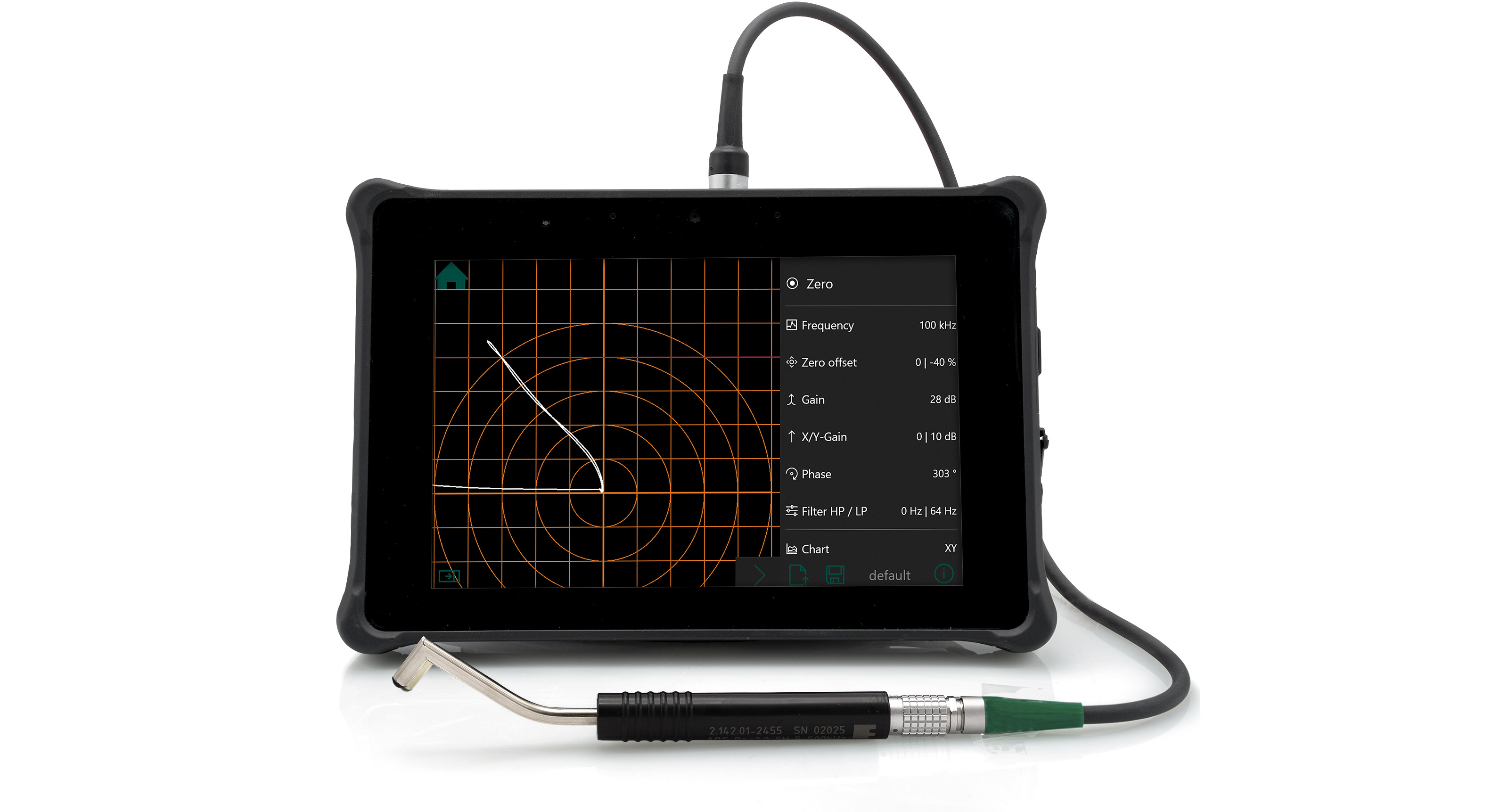

The TCM 2.142 combines crack detection, conductivity verification, and large-area scanning in a single platform.

One Platform. Multiple Tests. Complete Confidence.

Crack detection. Material verification. Large-area inspection. The TCM 2.142 unifies them all into one rugged, mobile system for faster, simpler, and more reliable results.

In industries where safety and reliability are non-negotiable, inspections can’t afford compromise. Traditionally, testing means juggling multiple devices. Every switch wastes time, increases training needs, and risks errors.

The TCM 2.142 changes everything. Built as a unified mobile platform, it brings together FOERSTER’s proven technologies — DEFECTOSCOP, SIGMATEST, and Eddy Current Array (ECA) — into a single system that adapts to your workflow and ensures 100% inspection confidence.

Why Choose the TCM 2.142?

Because one platform does it all — delivering faster, more reliable inspections without the complexity of multiple devices.

Multi-Frequency Power

Reach Anywhere

Eddy Current Array

Field-Ready Design

Efficiency Boost

A Solution Built for Real-World Inspections

Here’s how the TCM 2.142 addresses the toughest testing challenges and simplifies inspections across industries.

The TCM’s multi-frequency inspection runs up to 8 frequencies in parallel, revealing both surface and subsurface defects in a single workflow.

The TCM supports rotating probes and a hand-held rotating head (up to 3000 rpm) designed for boreholes and other complex geometries.

Specially designed weld seam probes can quickly inspect for defects in welds.

The Eddy Current Array (ECA) module scans broad or irregular surfaces with up to 512 probe elements. This ensures complete coverage, accurate defect localization, and automatic documentation.

Yes. With its rugged IP66 housing, 1.5 m drop resistance, and an 8” HD sunlight-readable display, the TCM is built for tough environments. It also offers voice commands (ZERO, FREEZE) for hands-free operation.

The TCM uses intuitive app-style software and automatic probe recognition, so even new operators can set up inspections quickly and achieve reliable results.

Absolutely. By consolidating crack detection, conductivity measurement, wall thickness checks, and array inspections into one system, the TCM reduces downtime, lowers equipment costs, and ensures 100% inspection coverage.

Extremely. The TCM can perform sorting tests, verify conductivity on aircraft structures, and detect cracks in bridges, rails, or ground surfaces — even as shallow as 20 μm.

Yes. Its wide frequency range supports different material thicknesses, while shielded probes minimize edge effects. Probes with titanium protection ensure long service life, and automatic calibration curve loading provides consistent accuracy.

The TCM works with absolute, difference, and cross-wound probes, each suited to different defect orientations. FOERSTER also offers custom probe shapes, titanium-protected probes for harsh conditions, and array probes with up to 512 elements.

FOERSTER provides calibration standards for cracks and conductivity, traceable to internationally recognized labs (NPL, PTB). These ensure repeatability, high sensitivity, and confidence in every measurement.

Yes. Docking the TCM transforms it into a full workstation with an Intel processor and Windows 10, so you can write, edit, and export reports directly from the device.

Very. A shoulder strap supports hands-free mobility, while extended runtime batteries (with quick-charge capability) keep you running in the field.

All-in-One Confidence in Every Inspection

See how the TCM 2.142 brings multiple eddy current testing methods together in one rugged mobile platform. Explore the infographic and share it with your team.

Versatility Where It Matters Most

Industry |

Challenge |

How TCM Helps |

|

Automotive |

Stress on axles, steering parts, EV housings |

Crack detection, conductivity checks, and large-area scans in one workflow |

|

Aerospace |

Heat damage and hidden flaws in fuselage panels |

Conductivity verification + sensor array scanning for full coverage |

|

Rail & Infrastructure |

Cracks in wheels, rails, and bridges |

Multi-frequency sensitivity + efficient large-area scanning |

|

Energy |

Inspections in tough, hard-to-reach conditions |

Rotating probes for boreholes, rugged design for field use |