Magneto-Inductive Testing That Fits Your Production Line and Your Budget

Detect hardness, case depth, and material mix-ups with in milliseconds, using a compact system that’s easy to integrate and simple to operate.

Simple, Scalable Material Property Testing

From missed defects to wasted parts and long QA delays, traditional hardness testing methods introduce risk and inefficiency into modern manufacturing. The MAGNATEST TCL is purpose-built to solve the everyday challenges of quality assurance in heat-treated and precision-manufactured components.

Instead of scrapping good parts, waiting for lab results, or catching issues too late, the MAGNATEST TCL helps you take control of quality. It is fast, easy to use, and delivers the reliable results you need to stop wasting parts and identify defects before they become big problems.

Designed for both in-line and manual testing environments, the MAGNATEST TCL gives you reliable go/no-go results at millisecond speeds — without the complexity or cost of more advanced systems.

Built for Demanding Environments

The MAGNATEST TCL delivers without compromising precision, performance, and safety. Whether you are integrating it into a high-speed production line or a QA lab, the TCL adapts to your workflow, providing fast, reliable material property verification that meets the strictest industry standards.

Automotive

Aerospace

Fasteners

Medical Devices

Energy

Agricultural Equipment

A Solution Designed to Solve Real Problems

Here is how the MAGNATEST TCL tackles the challenges that matter most to your operation.

The MAGNATEST TCL utilizes magneto-inductive technology to evaluate material properties, including hardness and case depth, without any damage to the part. You will save time and preserve every part, all while getting immediate, go/no-go feedback.

With material mix-up detection, the MAGNATEST TCL instantly flags incorrect alloys or components using conductivity and permeability differences so you can prevent costly errors before they move downstream.

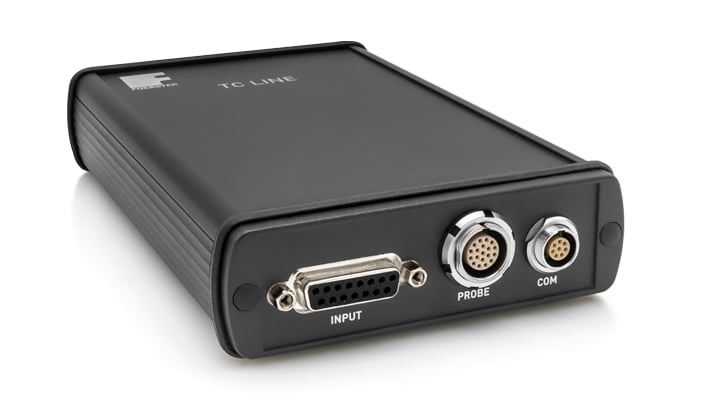

The MAGNATEST TCL features a compact footprint and integrates easily into new or existing manufacturing processes. It connects via discrete I/O or ProfiNet, and its modular design supports both in-line and lab-based configurations.

With millisecond-level test times, the MAGNATEST TCL is designed for speed and efficiency, supporting 100% part inspection even in fast-paced, fully automated environments like automotive and aerospace manufacturing.

The automatic probe recognition and touch-optimized software make it easy for operators to switch between parts or lines with minimal downtime, with an intuitive test parameter setup.

With real-time go/no-go results, the MAGNATEST TCL allows you to catch problems at the source. That means you can stop the process immediately, not after a defective part has reached the next station (or your customer).

Highly Versatile for Quality Control

Explore our product infographic to learn more about the MAGNATEST TCL. Share it with your team.

.png?width=1920&height=960&name=Blog%20Post%20-%20Large%20Hero%20Image%20(3).png)