Needle bearing test system

Industry

Industrial manufacturing

Challenge

To test for heat treatment on small sized needle/pin bearing rollers at a high rate of speed.

Results

The test system of FOERSTER is capable of mechanically processing 10-15 parts per second, contingent upon the performance of the test electronics. It features a highly compact design that is both easy to maintain and operate.

Key Products

MAGNATEST Product Family

Back to the Landingpage Customized Solutions for components testing

The Challenge

To rapidly test for heat treatment on small-sized needle/pin bearing rollers poses a significant challenge due to the parts' small diameter and length. Ensuring that each part passes through the test coil individually and is accurately sorted is particularly demanding for components of such minute dimensions.

The FOERSTER Solution

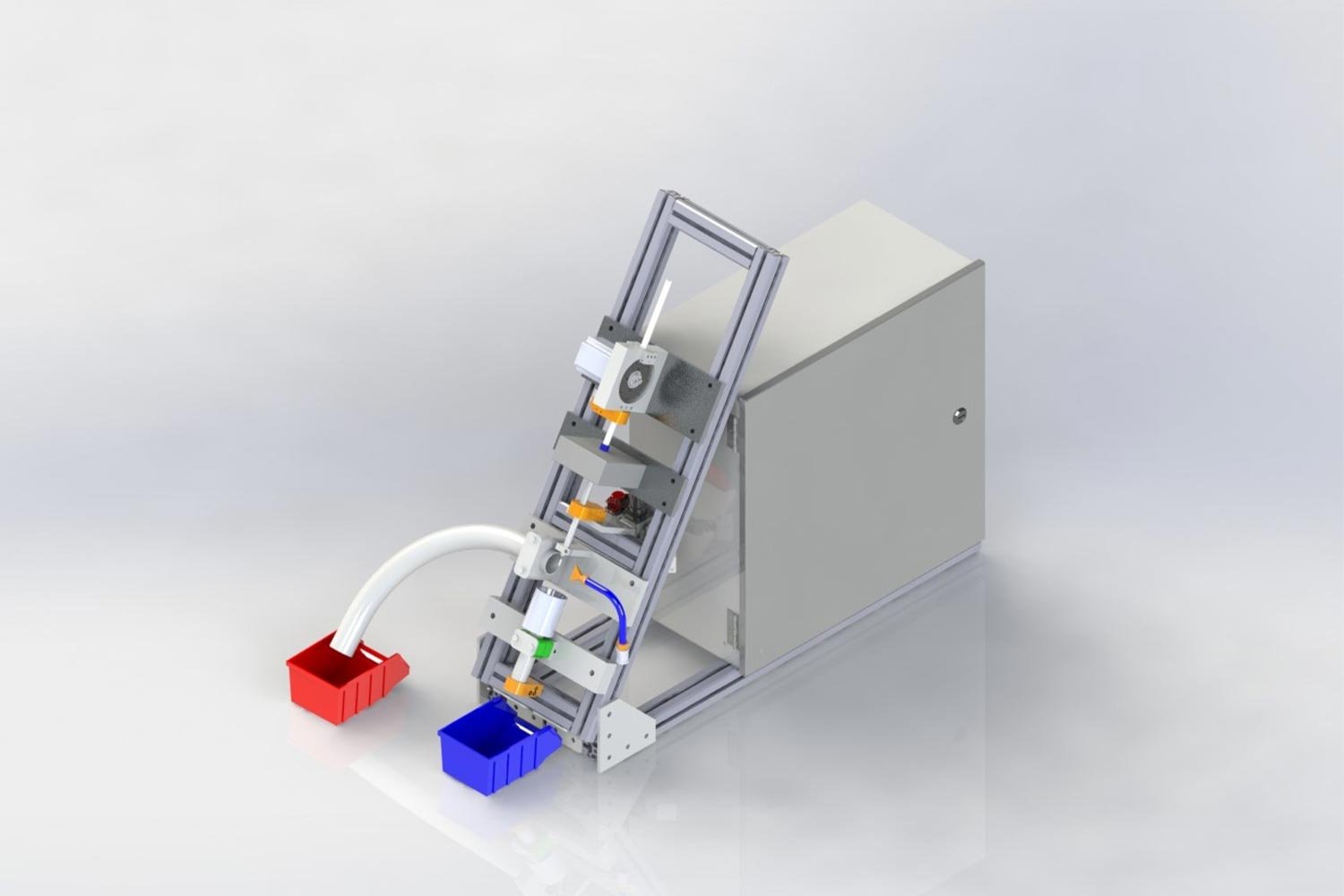

The FOERSTER system incorporates a precisely engineered slotted wheel with adjustable rotation speed to facilitate simultaneous loading and unloading of parts. A straightforward guidance mechanism directs the small bearings through the center of an encircling coil, where the test is automatically triggered. Sorting is efficiently managed by an air blowoff, directing defective parts into a designated bin.

Specalties worth mentioning

Adjusting for varying part lengths and diameters can be easily achieved using simple hand tools and by swapping the rotational tooling wheel. Each specific part number is assigned a dedicated tooling wheel to ensure precision. The system requires minimal maintenance to operate efficiently and boasts a compact design. Additionally, it features a PLC and a small touch screen to facilitate both manual and automatic functions.

Results

The system is capable of mechanically processing 10-15 parts per second, contingent upon the performance of the test electronics. It features a highly compact design that is both easy to maintain and operate.

Back to the Landingpage Customized Solutions for components testing