Pitman shaft inspection system

Industry

Automotive

Challenge

To test steering shafts for cracks in automotive applications. Some of the tested areas consist of complicated part geometries and need special test equipment setup.

Results

The testing performance achieves the remarkable feat of inspecting, engraving, and grading one part every 10 seconds.

Key Products

STATOGRAPH

Back to the Landingpage Customized Solutions for components testing

The Challenge

The objective is to inspect steering shafts for cracks in automotive applications. The so called pitman shafts are used inside the steering box of a car. Due to the intricate geometries of some tested areas, specialized test equipment is required. This is crucial for both safety and functionality. The system not only inspects and sorts parts for cracks but also engraves a barcode at a specific location using a laser, and verifies the barcode's readability to ensure part traceability.

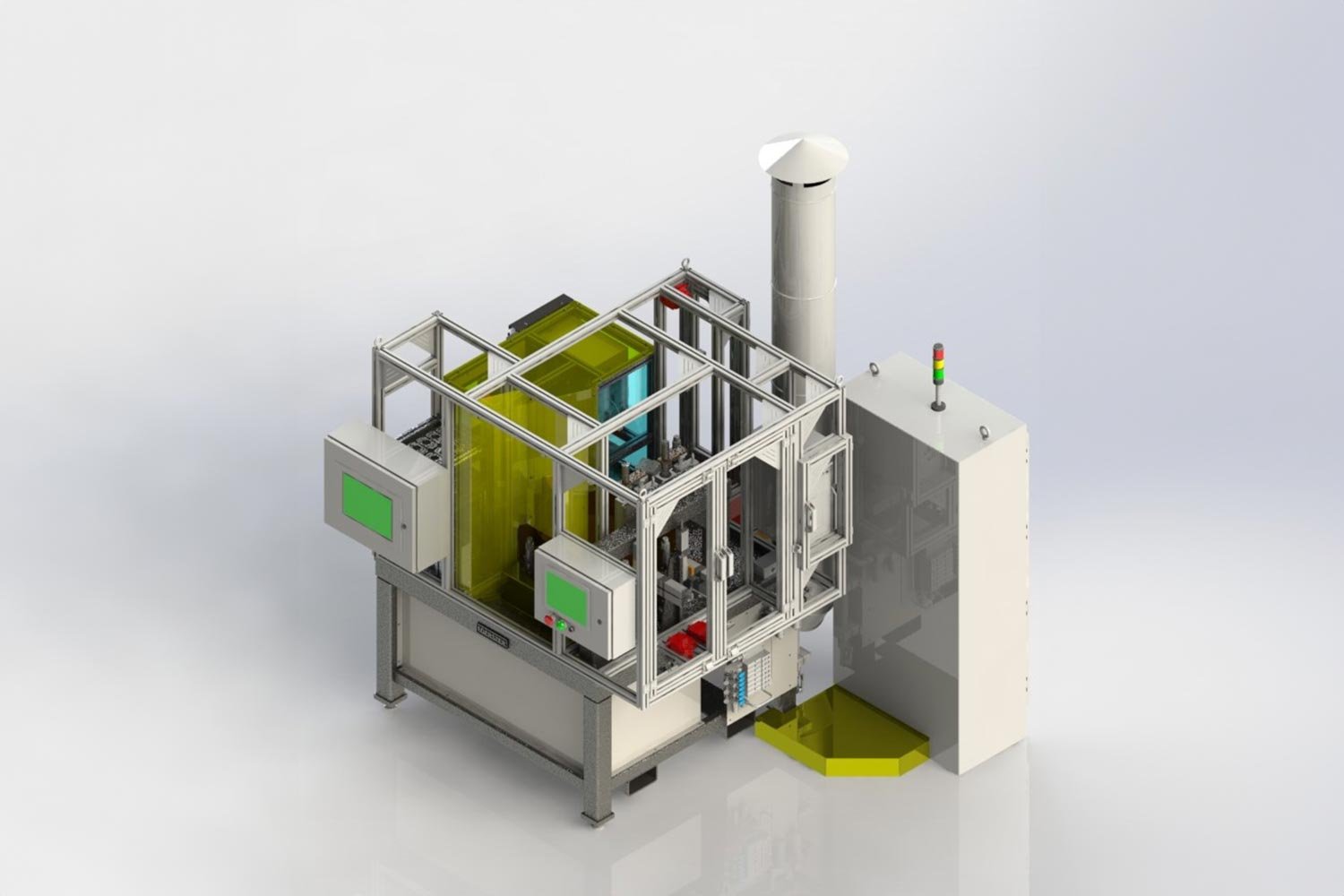

The FOERSTER Solution

The fully automated test system of FOERSTER accommodates both automated and manual loading and unloading options. It performs crack testing, barcoding, and barcode grading with an impressive throughput of one part every 10 seconds. The system also features comprehensive part tracing capabilities, enabling seamless communication with company-level 2 operations.

Specalties worth mentioning

The testing of gear teeth and shaft splines presents significant challenges, which are expertly handled by our system. Additionally, the capability to engrave barcodes using a class 4 laser (with necessary safety enclosures) is a crucial feature that underscores the system's advanced functionality.

Results

The testing performance achieves the remarkable feat of inspecting, engraving, and grading one part every 10 seconds. This level of efficiency not only boosts productivity but also ensures that each component meets the highest standards of quality and traceability. The automation of these processes minimizes human error, maximizes throughput, and guarantees consistent inspection accuracy. With such rapid and reliable performance, manufacturers can maintain seamless production lines and uphold stringent safety and quality regulations, ultimately delivering superior products to the market with unparalleled speed and precision.

Back to the Landingpage Customized Solutions for components testing