Sintered metal valve guides test system

Industry

Automotive

Challenge

High speed crack detection of sintered metal valve guides for automotive cylinder heads.

Results

Our testing demonstrates that the system can achieve speeds of up to 10 parts per second. In practical applications, customers typically operate the system at approximately 5 parts per second to align with their production needs.

Key Products

STATOGRAPH CM/TCL

Back to the Landingpage Customized Solutions for components testing

The Challenge

High-speed detection of cracks in sintered metal valve guides for automotive cylinder heads. The powder metal process involves a top and bottom die that converge to form the part and then separate to release it. Occasionally, during this separation, the green part valve guide gets stuck in both die halves, resulting in a light pull from each end and causing a radial crack around the center of the part (length-wise).

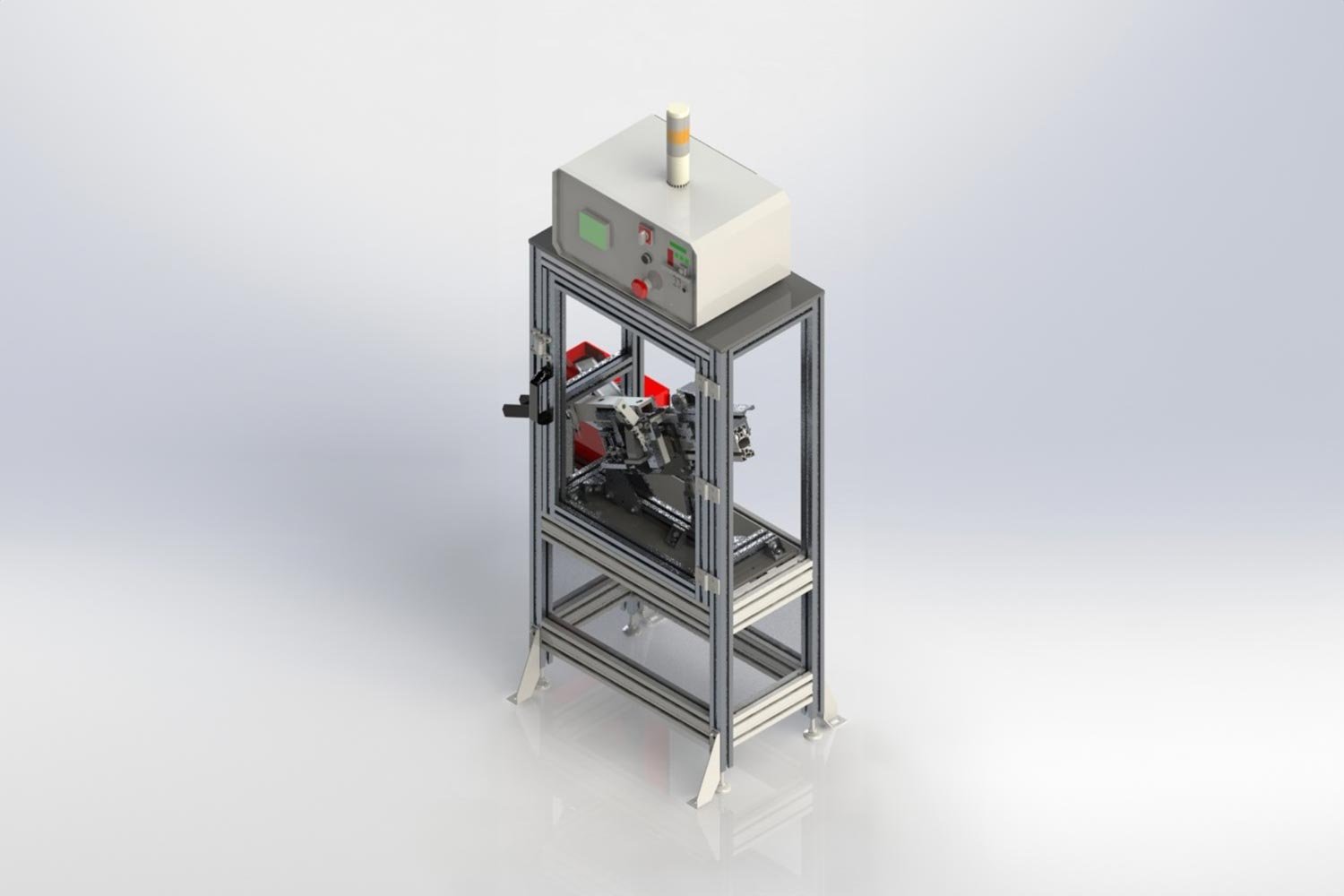

The FOERSTER Solution

The system is engineered for effortless integration with the production line, seamlessly receiving valve guides directly from the sintering process via a chute and positioning them for subsequent grinding. It utilizes a Programmable Logic Controller (PLC) to deliver real-time pass/fail results and maintain an accurate tally of inspected parts. The modular design allows for the quick and easy interchange of encircling sensors to accommodate various diameters, using simple hand tools for efficient sensor swaps.

Specalties worth mentioning

The system features a streamlined design with cost-effective wear components, ensuring easy and straightforward maintenance. It is highly versatile, capable of accommodating a wide range of part diameters. The line speed can be intuitively adjusted via a touch screen interface to align with the customer's production rate. Furthermore, the automated test activation is efficiently managed by thru-beam sensors placed strategically before and after the encircling sensor. A flexible printed sensor, wrapped around a 3D printed spool and holder, functions similarly to a TS DMAT LMD/HMD differential coil, enabling the detection of transverse-oriented defects around the valve guide diameter.

Results

Our testing demonstrates that the system can achieve speeds of up to 10 parts per second, showcasing its remarkable efficiency and capability. This high throughput is a testament to the system's advanced engineering and robust design, which ensures reliable performance even at maximum operational speeds. In practical applications, however, customers typically operate the system at approximately 5 parts per second. This operational pace is often chosen to harmonize with their specific production workflow and ensure optimal integration with other processes. By doing so, customers can maintain a balanced and efficient production line while still benefiting from the system's high-speed detection capabilities. This flexibility not only enhances the overall productivity but also allows manufacturers to adapt quickly to varying production demands without compromising on the quality of inspection.

Back to the Landingpage Customized Solutions for components testing