Turbine blade inspection system

Industry

Aerospace

Challenge

To automate MAGNETOSCOP testing on hot side turbine blades in aerospace and energy applications, addressing wall loss and degradation due to erosion.

Results

The performance is tailored to the specific size and testing requirements of each part, delivering significantly faster results compared to traditional manual microscopic analysis.

Key Products

MAGNETOSCOP

Back to the Landingpage Customized Solutions for components testing

The Challenge

To automate MAGNETOSCOP testing on hot side turbine blades in aerospace and energy applications, addressing wall loss and degradation due to erosion. The primary challenge was to mitigate any magnetic signature interference arising from robot movement and gripper tooling. To overcome this, the probe holder was crafted from 3D printed plastics, ensuring no mechanical interference near the probe.

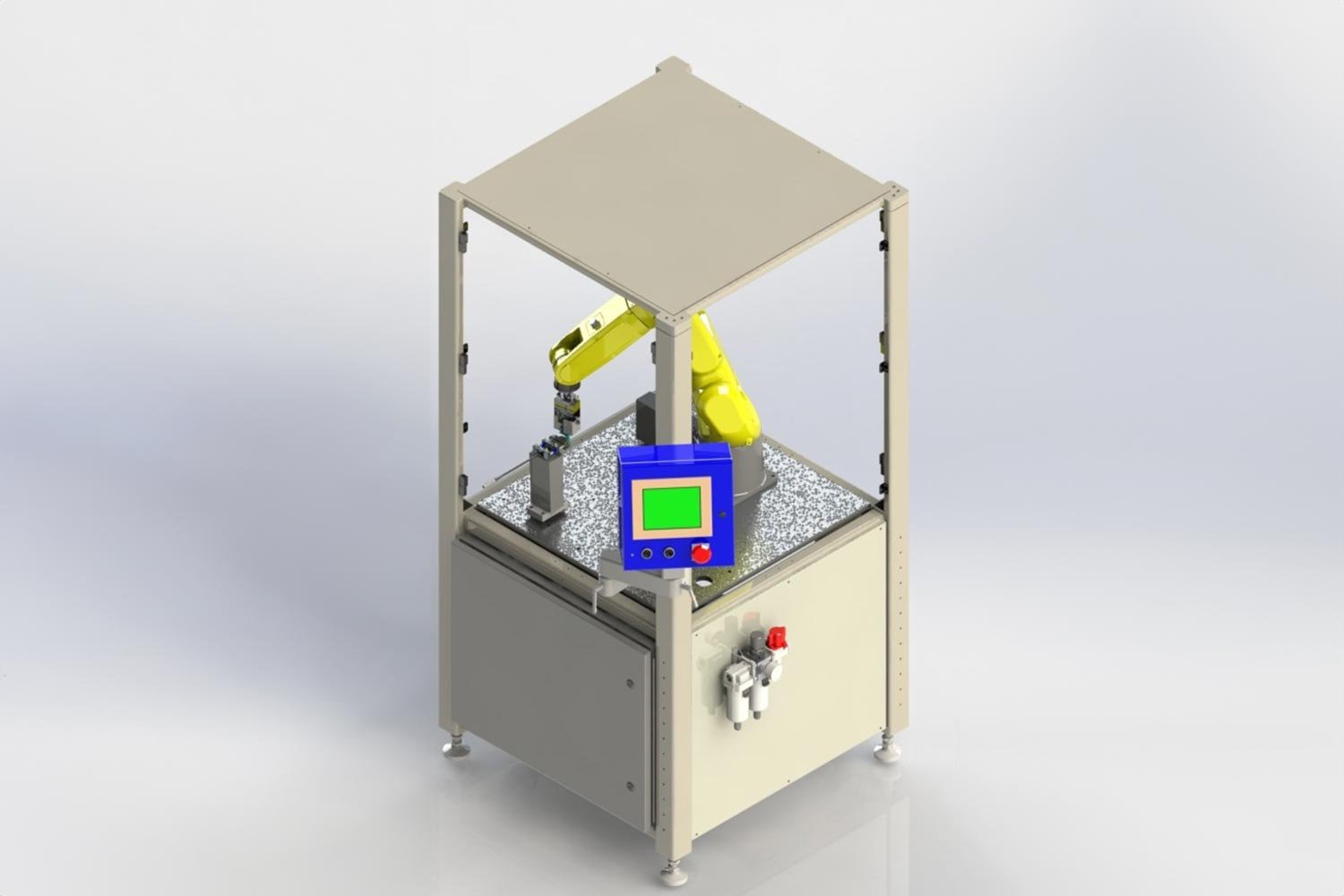

The FOERSTER Solution

A fully automated testing process within a robotic cell is integrated with the MAGNETOSCOP for precise wall testing of turbine blades. The robot expertly maneuvers the turbine blade using specialized gripper tooling to inspect designated areas as per OEM specifications. Measurements for each critical zone are meticulously recorded and linked to each part's serial number for comprehensive traceability. The system is manually loaded and unloaded using a parts cartridge during the maintenance, repair and overhaul process (MRO).

Specalties worth mentioning

The robot's movements can be precisely programmed, making it adaptable to various turbine blade sizes and geometries. This versatility allows the system to accommodate an array of blade designs without necessitating significant modifications or downtime. By tailoring its actions to the specific contours and dimensions of each blade, the robot ensures thorough and accurate testing. This adaptability significantly enhances operational efficiency, as it streamlines the testing process across different blade types, thereby reducing setup times and increasing throughput. The capability to easily reprogram the robot for diverse blade profiles underscores the system’s flexibility and its value as a scalable solution.

Results

Performance is tailored to the specific size and testing requirements of each part, delivering significantly faster results compared to traditional manual microscopic analysis. By automating the testing process, the system not only accelerates the inspection timeline but also enhances accuracy and consistency. Unlike manual methods that are prone to human error and variability, the automated solution ensures uniformity in testing, leading to more reliable data. This precision in measurement and rapid turnaround time translates into reduced downtime for maintenance, repair, and overhaul activities, allowing for quicker decision-making and improved operational efficiency. Furthermore, the detailed records linked to each part’s serial number provide a comprehensive audit trail, aiding in quality assurance and regulatory compliance. This holistic approach to testing not only boosts productivity but also elevates the overall quality and safety of the turbine blades, ultimately benefiting both aerospace and energy sectors.

Back to the Landingpage Customized Solutions for components testing