In the production of sintered hard metals and powder metallurgical components, magnetic quantities such as the weight-specific saturation polarisation σs as well as the volume-specific saturation polarisation Js correlate with a variety of important process parameters and material properties.

With the KOERZIMAT 1.097 MS, FOERSTER offers a measuring system for the precise, automatic and fast measurement of the weight-specific saturation polarisation σs as well as the volume-specific saturation polarisation Js. The largely geometry-independent measurement makes it possible to examine complexly shaped samples in particular. The KOERZIMAT 1.097 MS is used, among other things, to check the degree of sintering in the hard metal sintering process and to determine the tungsten content dissolved in cobalt as well as the free iron, cobalt or nickel content in powders / hard metals. In addition, the saturation polarisation Js in Tesla can be determined on soft magnetic circuit components.

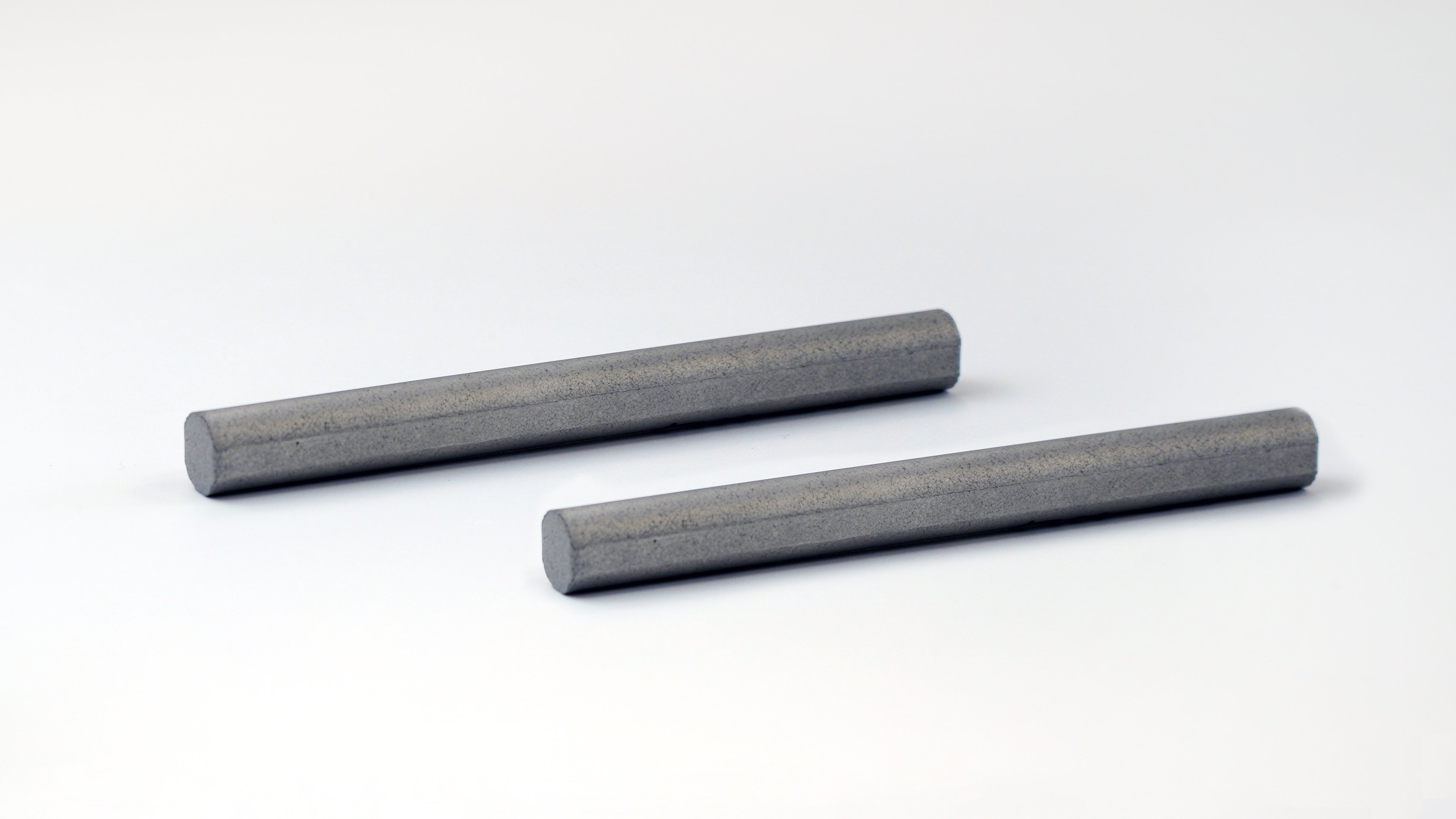

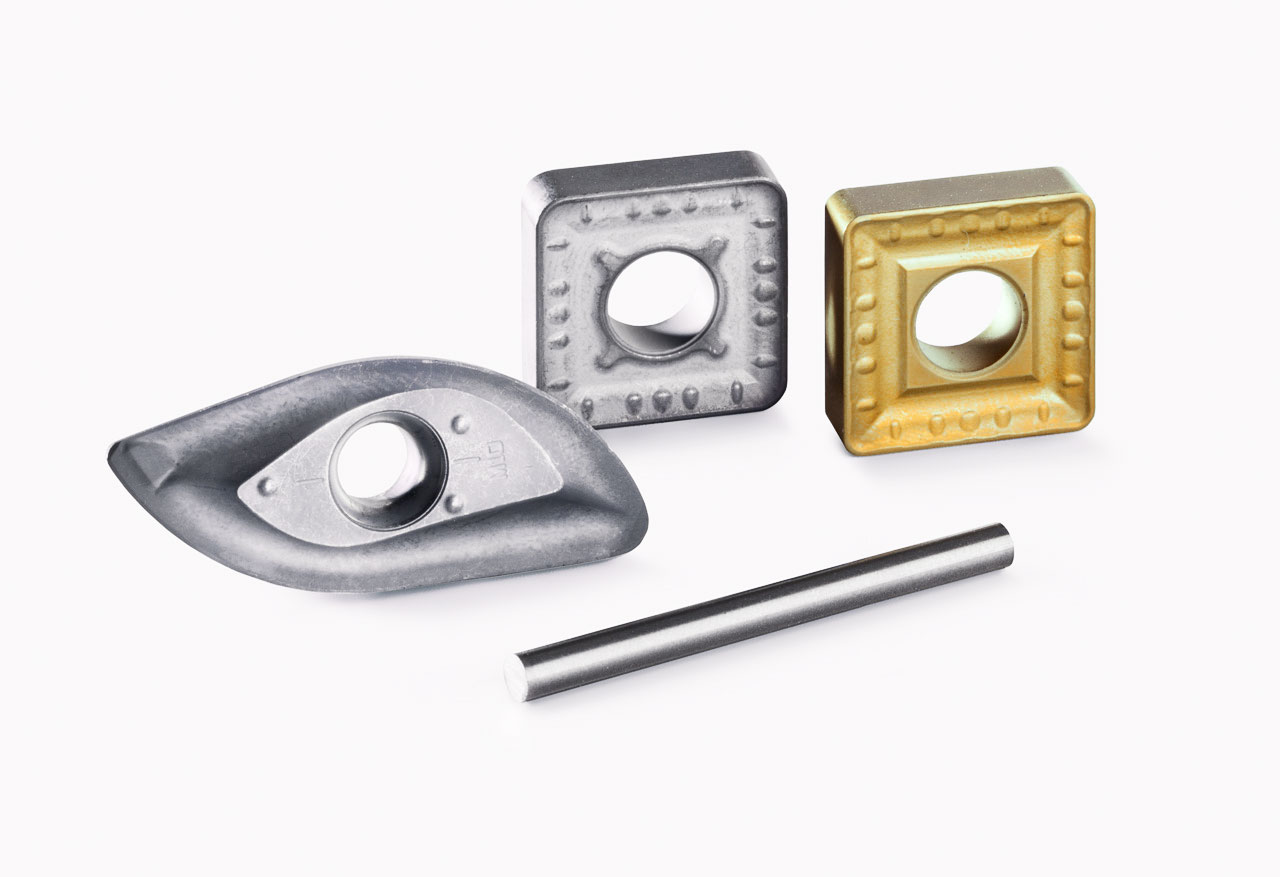

In the hard metal producing industry, magnetic parameters are used for analyzing the material’s microstructure. By measuring the coercive field strength on batch samples, it is possible to determine the grain size of the carbide quickly and non-destructively. This in turn provides inferences about the material’s resistance and hardness. For this reason, one of the prerequisites for good quality management in powder metallurgy is the ability to determine the coercive field strength with precision.

These parameters can be easily determined with the FOERSTER measuring instruments KOERZIMAT HCJ and KOERZIMAT MS.

When powdered metal is pressed into blanks, it can lead to cracks and changes in the microstructure, which in turn can cause the parts to burst during the sintering process. But high-performance tools such as drill bits, milling machines or lathes require the very highest quality. For this reason, FOERSTER offers the test instruments STATOGRAPH and MAGNATEST; before the sintering process, they are used to examine the blanks for cracks and microstructure fl was by means of eddy current. Volume reduction during the sintering process itself can also lead to cracks in the component – flaws that can be found and sorted out, again using eddy current.

Cutting tools must be able to withstand high loads. An assessment of the carbon balance after sintering provides an important quality parameter for this. When under-carburization occurs in the sintering process, the resulting ‘eta’ phase can make the tool brittle, leading to breakage. In the case of over-carburization, the carbon precipitates out, which can result in insufficient strength and wear-resistance and, again, tool breakage.

For this reason, the KOERZIMAT MS measuring system monitors the carbon balance by comparing the actual magnetic saturation (MS) with the nominal value.

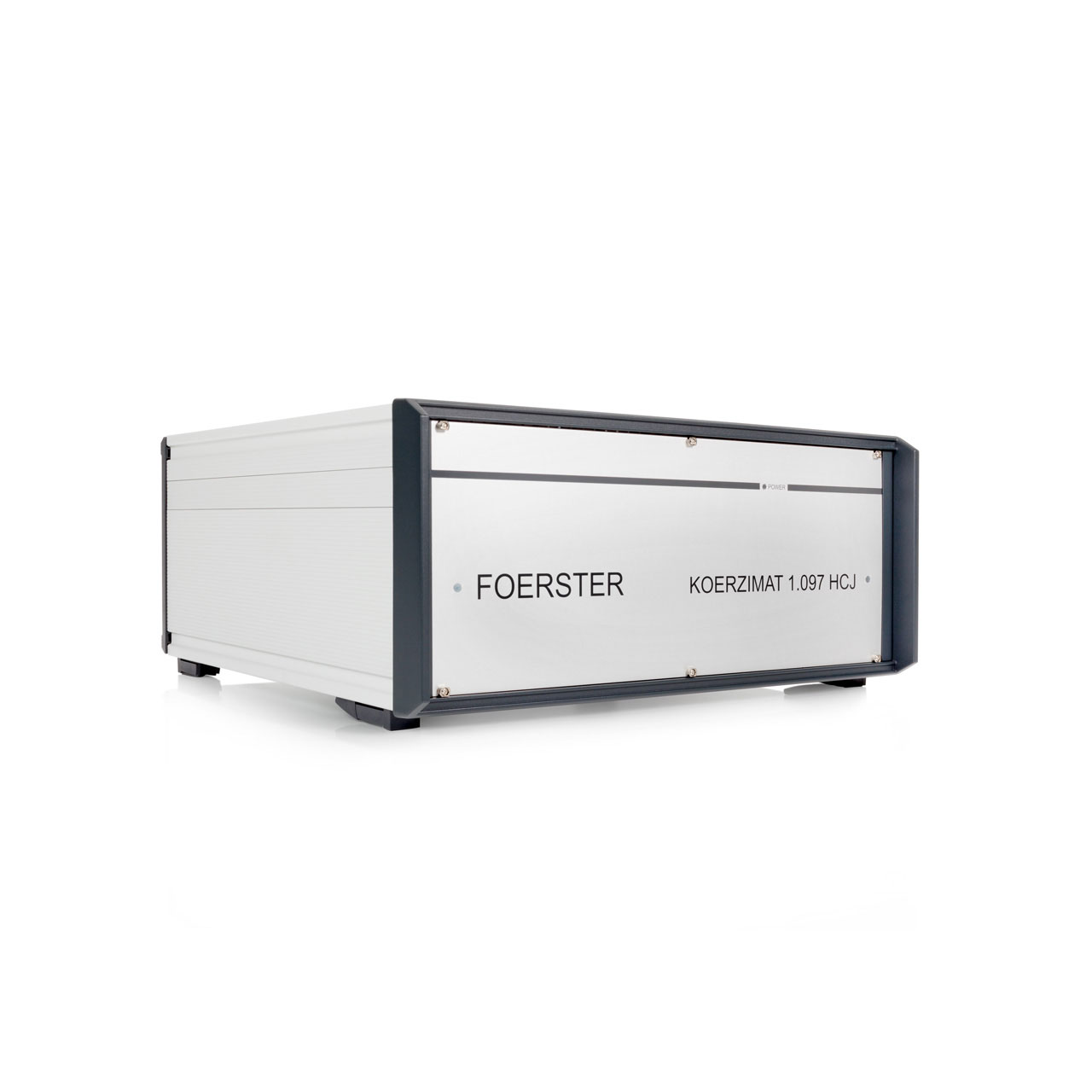

Especially brittle materials must be completely free of defects, such as pores that reduce the material density. It is therefore important to know whether the material has been sintered to the density that is, at least in theory, achievable. For this, one takes the coercive field strength HcJ. This parameter approaches a maximum that depends on the temperature and duration of the sintering. If the coercive field strength is too low, the density will also be less than the nominal value, indicating e.g. incomplete density sintering. For quality assurance, the KOERZIMAT HCJ measurement system can determine and monitor the coercivity on batch samples.

When a specific mechanical attribute is desired, one can use magnetic phases – like ferrite in duplex steels and martensite in austenitic steels – as indicators for controlling the production process. For example, a high proportion of martensite indicates brittleness and the associated risk of breakage. The KOERZIMAT MS monitors the magnetic phase after thermal treatment and cold forming. Measurement is fast and unaffected by the specimen geometry, and it requires no sample preparation beforehand.

The KOERZIMAT 1.097 measuring system by FOERSTER facilitates the accurate, automatic, and fast measurement of the weight-specific saturation polarization σs and volume-specific saturation polarization Js.

Learn more →

The KOERZIMAT 1.097 HCJ measuring system by FOERSTER facilitates the accurate, automatic, and fast measurement of the coercivity HCJ. The largely geometry-free measurement is particularly suitable for testing samples with complex shapes.

Learn more →Robert Augner

Non-destructive testing methods

Daimler AG

Jens Geiger

Director N-DECT

140 Industry Dr,

Pittsburgh PA,

15275