The SONODUR 3 provides two different technology standards for hardness testing: The UCI method (Ultrasonic Contact Impedance) and the Leeb method. The user-friendly SONODUR 3 is designed for rough everyday use.

The mobile high-tech all-rounder is used for quality control at incoming goods or during the production process. Another field of application is the fast hardness testing of metallic materials after heat treatment or surface processing. The system is also excellently suited for hardness testing at hard-to-reach positions and for mobile weld inspection in a confined space. A simple adjustment on almost all coarse-grained or heterogeneous materials (e.g. cast iron) complete the application areas of the SONODUR 3.

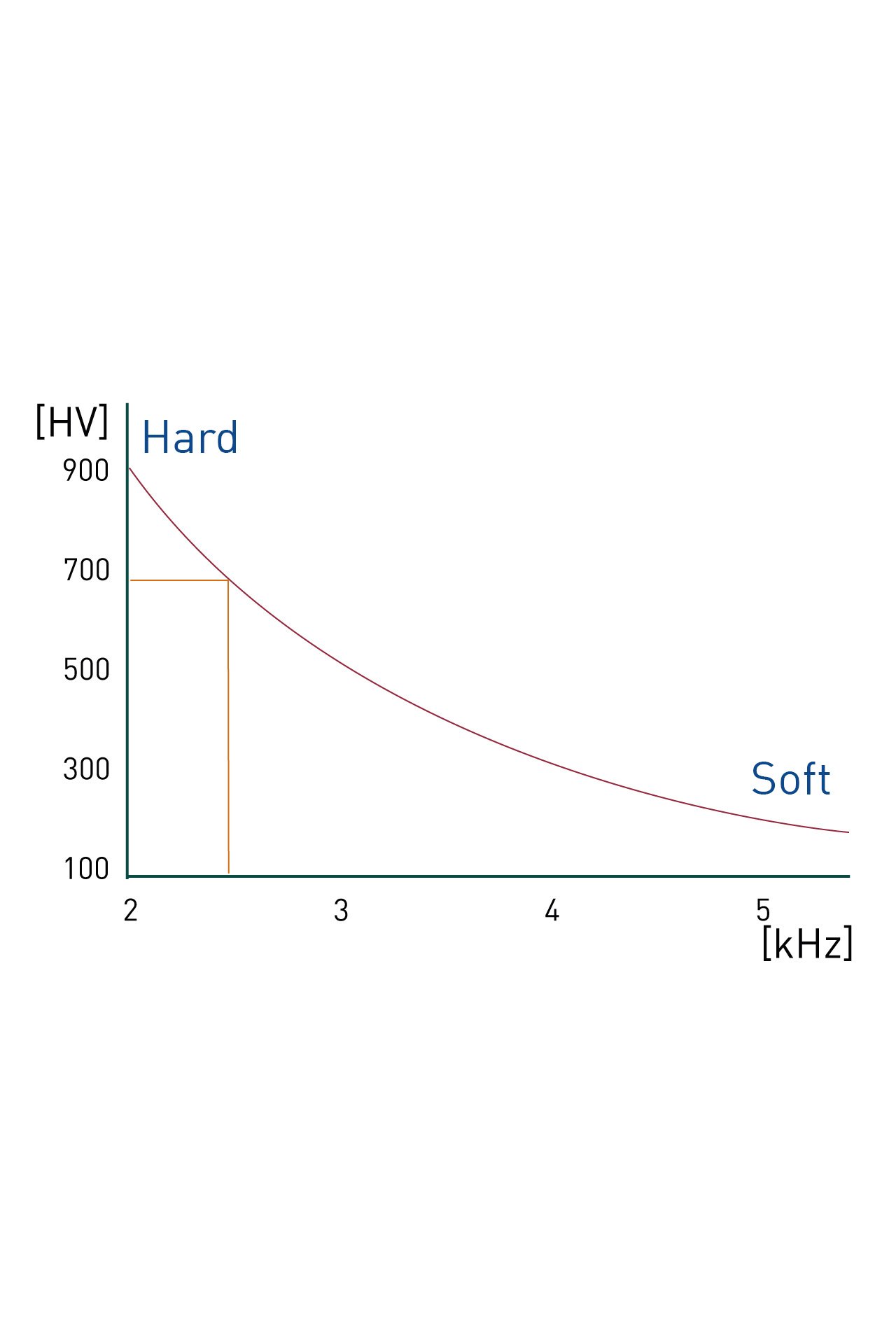

The rod of a UCI test probe is stimulated to oscillate in the longitudinal direction with its natural frequency. A diamond is soldered into the lower end of the rod, which is pressed into the material in order to perform a measurement. With it, a defined load is applied via a spring system. When the Vickers diamond penetrates towards the material, the vibration is damped and a frequency shift occurs, which can be measured. When the nominal test force has been reached within the final position, the hardness value is calculated from this frequency shift using the Vickers scale and will be displayed immediately. Due to the small indentation size and depth, the process is often considered to be non-destructive.

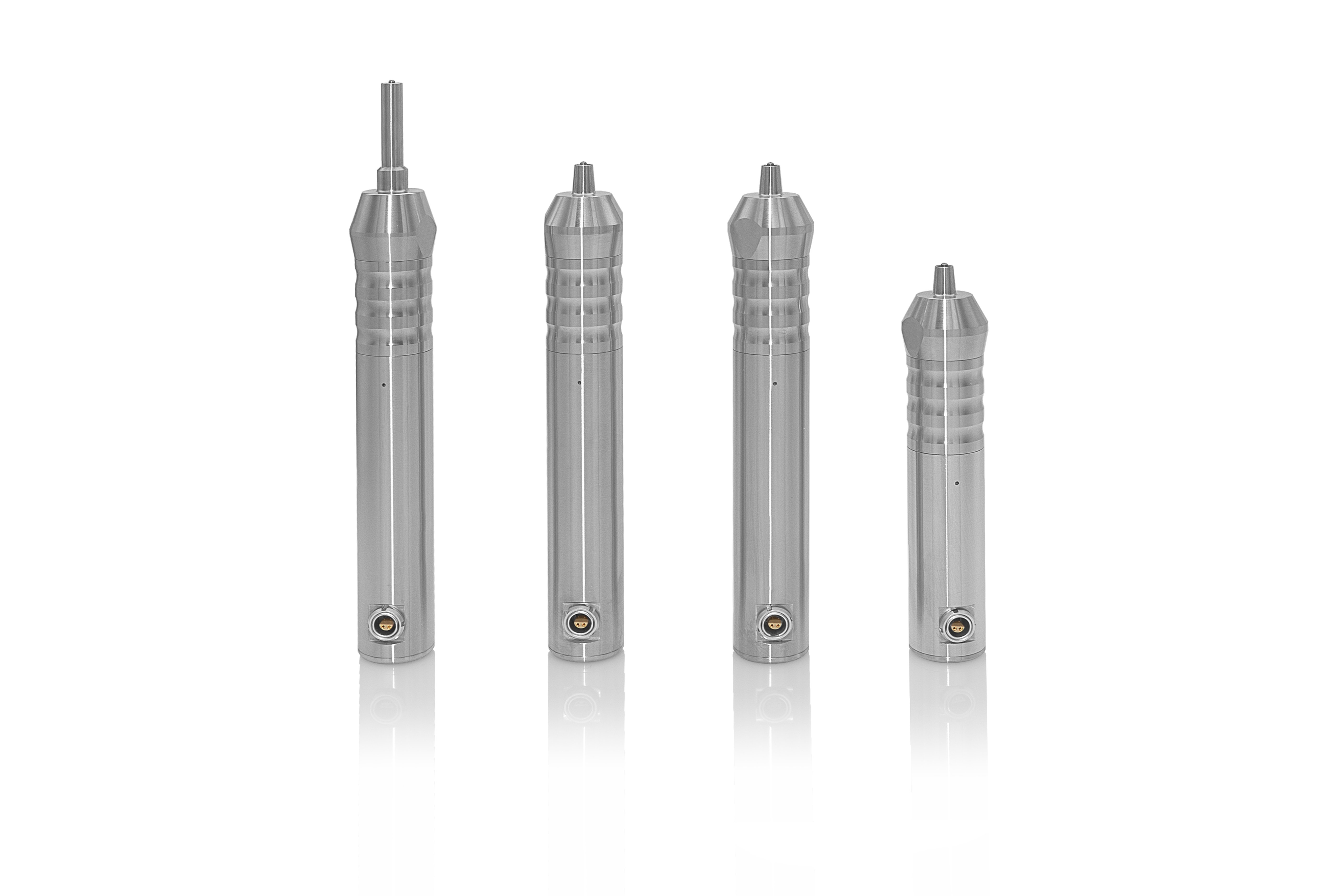

The hand-held measuring probes in robust stainless-steel housing are designed for daily use. They allow very accurate positioning measurements in any direction, simply by placing and pressing. The measured value is produced immediately when the nominal test force has been reached in the forward movement. No maintenance time is required by holding or lifting the probe to display the measured value.

The intelligent measuring system of each probe covers the entire hardness range of the classic Vickers scale. The hand-held probes are suitable for measurements of metals, industrial ceramics and, with certain restrictions, also for highly heterogeneous materials such as cast iron (nodular cast iron e.g. GJS500 or laminar graphite).

Our hand-held measuring probes with test loads from 10 N (HV1) to 98 N (HV10) are currently available for solving a wide range of testing tasks depending on component weight, thickness or geometry, with test probes and dimensions adapted to the task.

Don’t wast any time with the SONO H probe. FOERSTER offers you a robust probe for the everyday work. It allows accurate measurement, which testing results will show up immediatelly.

The perfect solution for hardness measurements in demanding positions is the SONO S from FOERSTER. It is optimized for testing on curved surfaces. That’s why the testing get more precise and reproducible.

Through repeatable and uniform force application, the SONO M from FOERSTER achieves highly accurate results. It covers the entire range of the classic #Vickers-scale. For an accurate positioning there are Probe feet to allow fast and secure results on different surfaces.

FOERSTER offers you the newest sensor technology for optimal test results with the SONO L. Working with the Leeb method the SONO L is perfect for the daily use on massive components in industrial environments. Having a “2-in-1-Concept” the probe allows the parallel use of the Leeb-sensors and the UCI-probes.

Hand-held probes can be conveniently placed on tooth flanks or involutes or be guided down to the tooth root using special test probes. The measurements can also be carried out without a protective sleeve in very confined spaces. Particularly difficult cases can be solved with motor probes in which the metallic support tube is used to guide the Vickers diamond safely. In this case, the support tube is placed where the Vickers diamond moves backwards and then the measurement process will be triggered.

The base material, narrow heat-affected zones and weld metals can be manually scanned with positioning accuracy, whereby HV10UCI is the most commonly specified. The fine test impression of the Vickers diamond allows a targeted measurement in the individual zones with individual device settings depending on the filler material, the test results of which can be individually stored and documented. Using the SONO-MPS1 magnetic test stand, the weld seam can be scanned transversely over a total distance of approx. 70 mm with fine adjustment to create an accurate profile of the weld seam.

SONODUR 3 is the only UCI hardness tester for aluminium that has material tables from EN ISO 18265 (Tab. F4/F5) and ASTM E 140 (Tab. T9) for the conversion of Vickers HV to Brinell or HRB, which can be significantly lower than for steel (78 HB, Table A1). It is also possible to measure components that are too thin, too light or too irregularly shaped for Leeb (rebound) or portable Rockwell.

HV10UCI (SONO-100H) hand-held measuring probes can be used to test heterogeneous (GJS) and inhomogeneous (GJL) cast iron materials due to the largest possible test indentation for UCI probes. A dedicated instrument setting is selected for each casting quality to optimally compensate for the influence of Young's modulus on the measurement. Graphite usually forms a relatively low concentration and spatial extent with 3 to 4 % of the total matrix, so that graphite nests hit by the Vickers diamond only represent individual outliers in the test record. These can be easily excluded from the results list. Experience has shown that 10 to 15 individual measurements can lead to a viable result (average) with a repeatability of about 10 to 15%. Laminar casting can be locally different depending on the cooling process, which may require special measures for comparability with Brinell (HB5 preferred). Components that are too thin, too light or too irregularly shaped for Leeb can also be measured here, as with aluminium.

Dirk Heyden

Process Planer Metallography, Tensile Testing and Hardness Testing

Lufthansa Technik AG

Clearly arranged and a user-friendly design. It allows direct access to the measurement menu and the measurement functions.

The use of familiar functions from the smartphone, such as screenshots and photography.

Prevents the unintentional triggering of a function when the touch screen is affected during carrying and measuring.

Easy to manage by exporting files via USB, Bluetooth, NFC or WLAN.

A Better overview and decision-making (e.g. for identification of measurement outliers) through color markings and calculation of percentage variations from tolerance values.

Presentation of measured hardness values in Vickers can be displayed in all other common hardness scales.

140 Industry Dr,

Pittsburgh PA,

15275