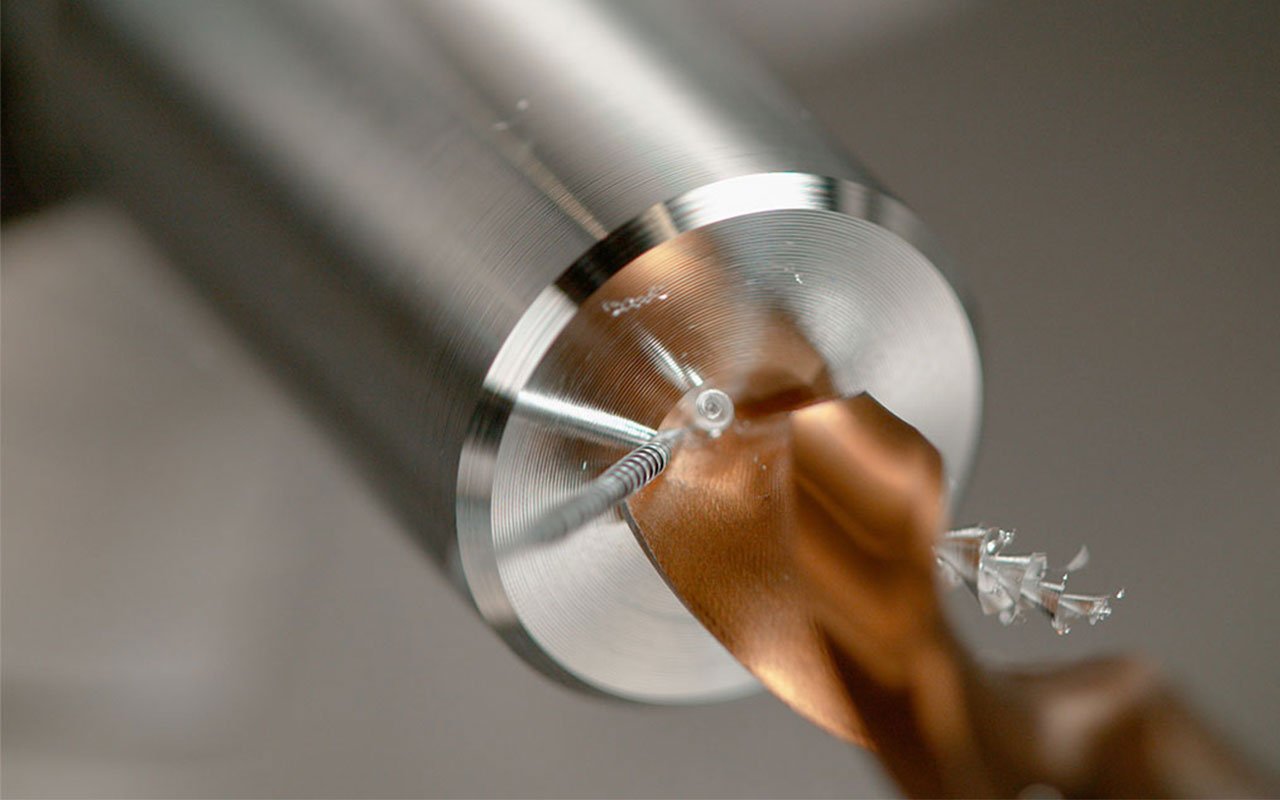

Magnetized components can lead to all sorts of problems

in the production process. For example, during grinding,

punching or drilling, metal chips and debris may be

present, which can lead to surface damage in subsequent

processes. Or interfering signals arise due to remanence

during the crack or structure test with eddy currents. This

in turn leads to incorrect statements about the component

condition and false results are given.

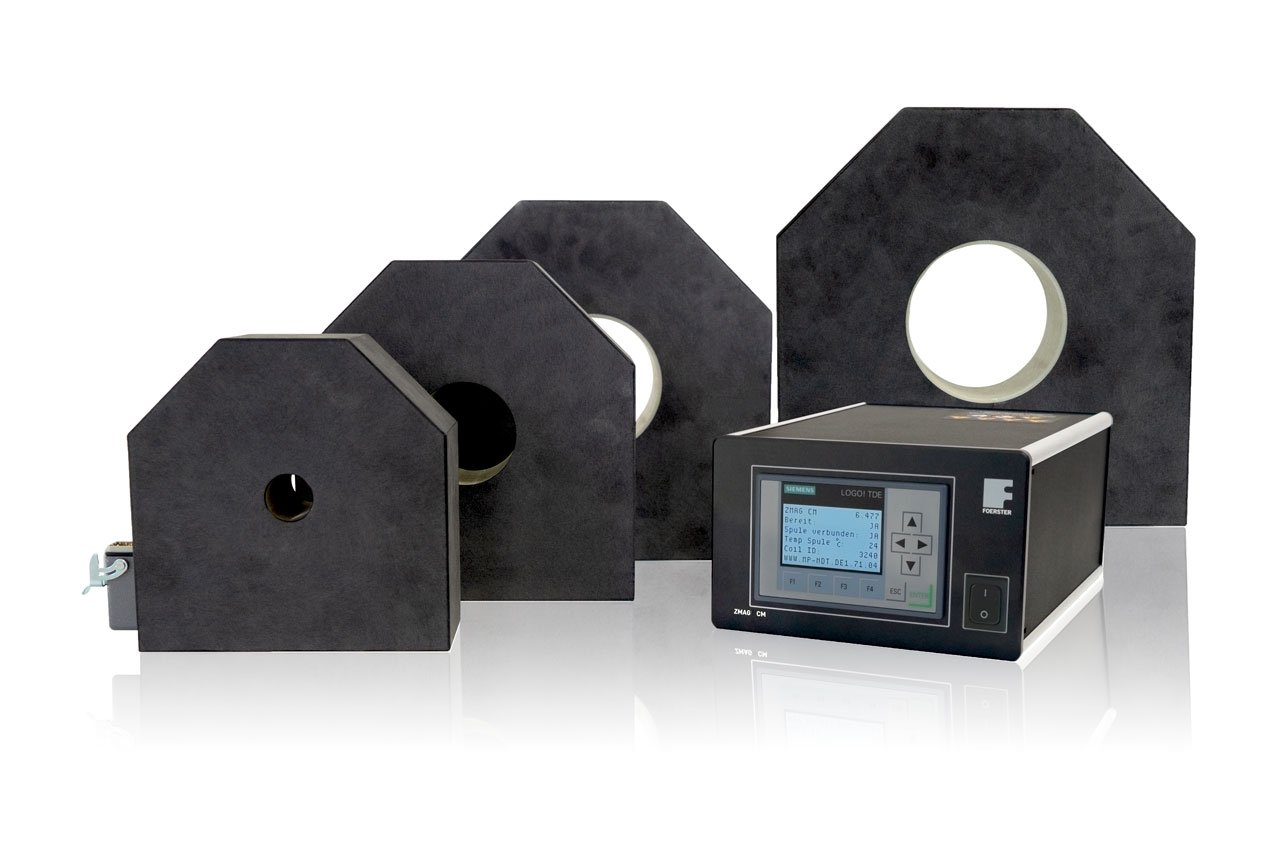

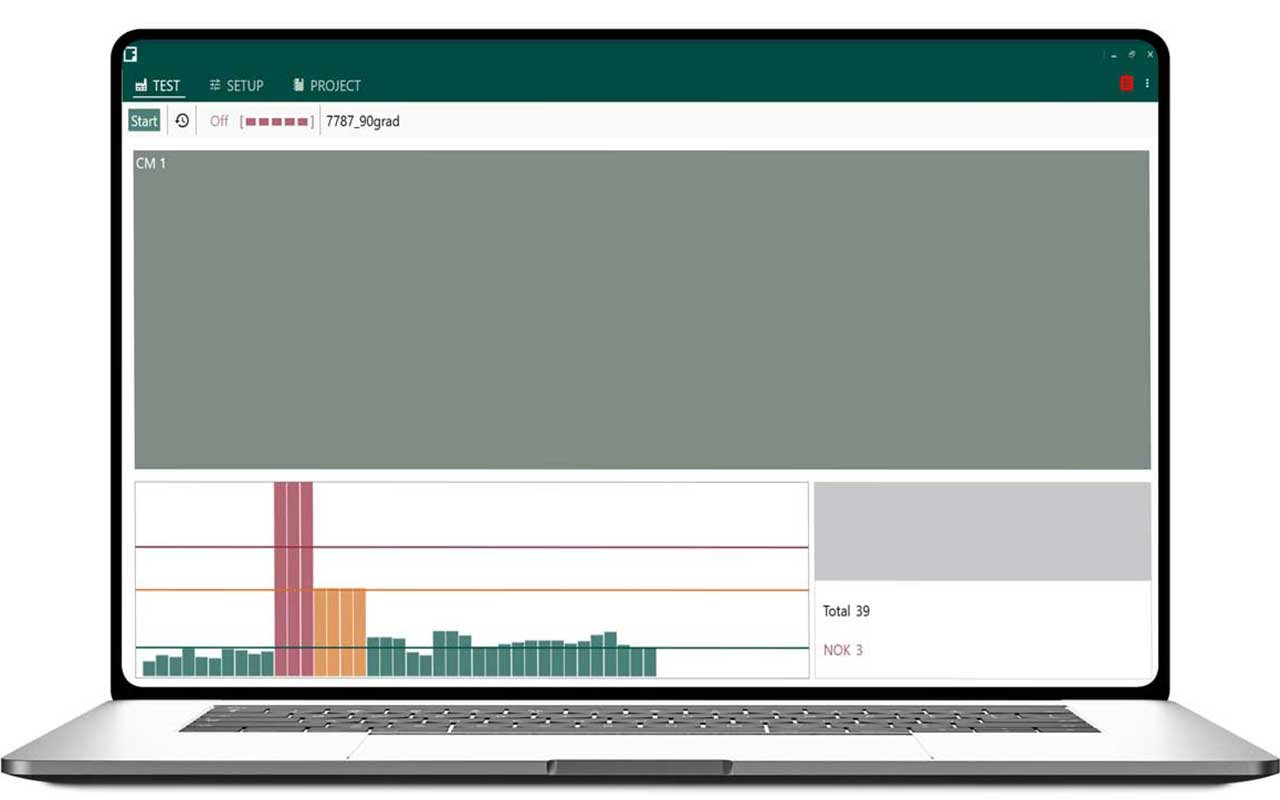

To avoid this from happening, FOERSTER offers you an appropriate

solution: the powerful demagnetization unit ZMAG

CM.

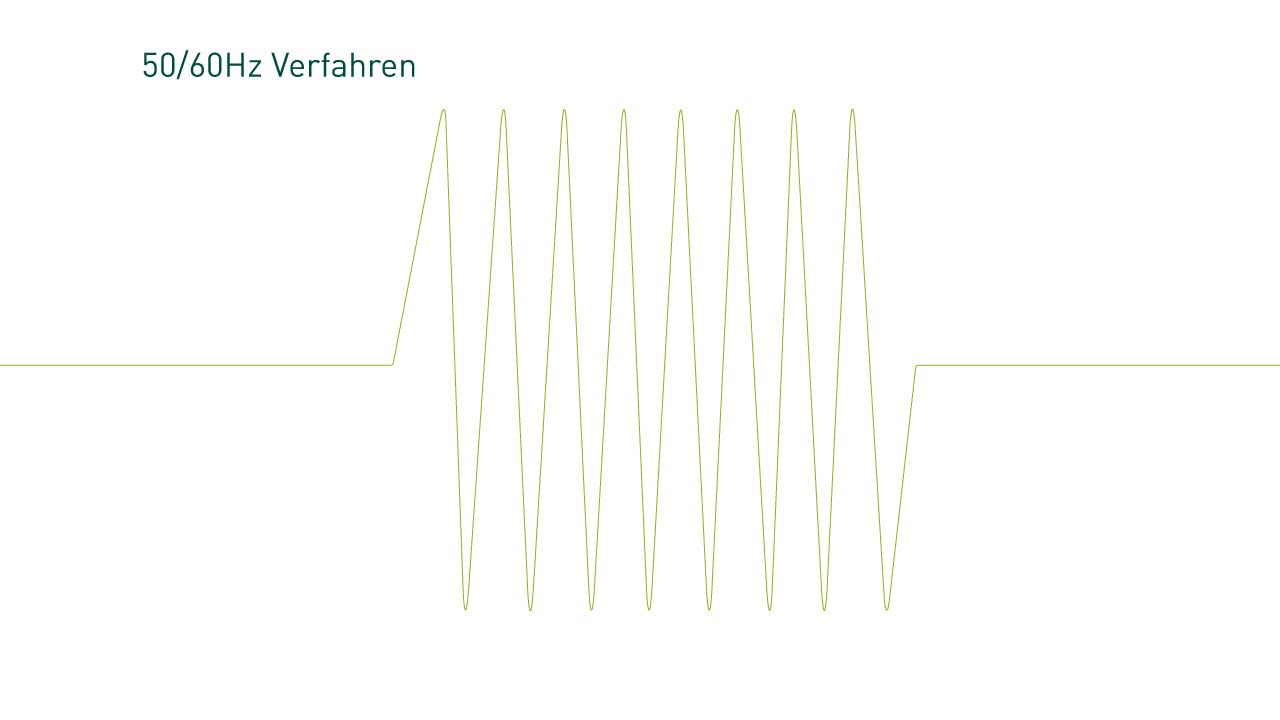

Unlike other units, the ZMAG CM does not use a continuous

signal but the so-called pulse method. This enables

a higher penetration depth to demagnetize the components

effectively and quickly. We deliver the ZMAG CM already

preconfigured, so that you do not need to make any further

adjustments. In addition, the Siemens control system

allows easy integration into your production process. Increase

your process quality and reliability now.

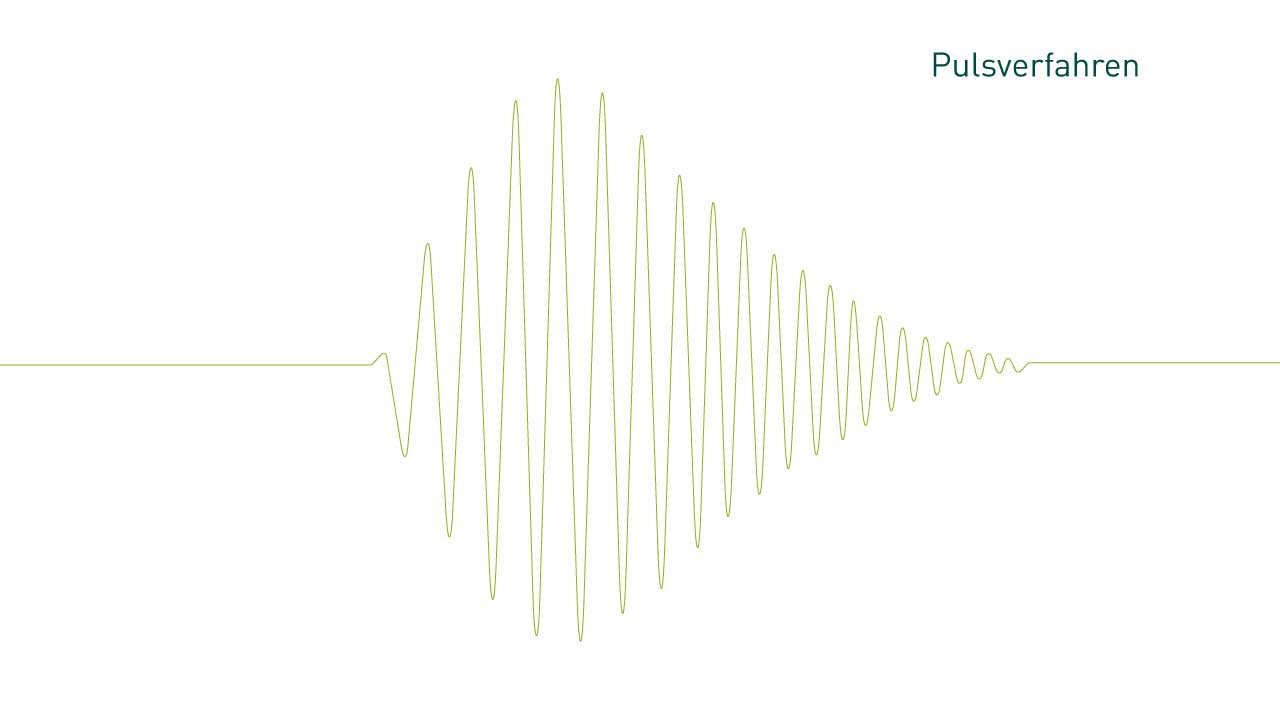

The ZMAG CM magnetization unit is operated with the pulse method. An approach that uses an alternating current pulse that flows through an appropriate coil. As a result, an alternating magnetic field that corresponds to the current is generated.

Components are positioned in the coil for subsequent demagnetization. The pulse can be triggered automatically via the connection to the PLC. This can also be done manually with a remote control. With complex geometries of the components it may be necessary to trigger the pulse several times while changing the components’ position. This ensures the thorough demagnetization of the component.

The ZMAG CM degaussing unit is preconfigured according to the coil and the component. The current is fed based on a programmed demagnetization curve. The current pulse is reproducible and independent of the operator of the system.

The pulse method enables high field strengths due to the comparatively low heat generation. This allows for a greater penetration depth than with a constant frequency. As a result, the residual magnetization is significantly lower in contrast to a continuous signal.

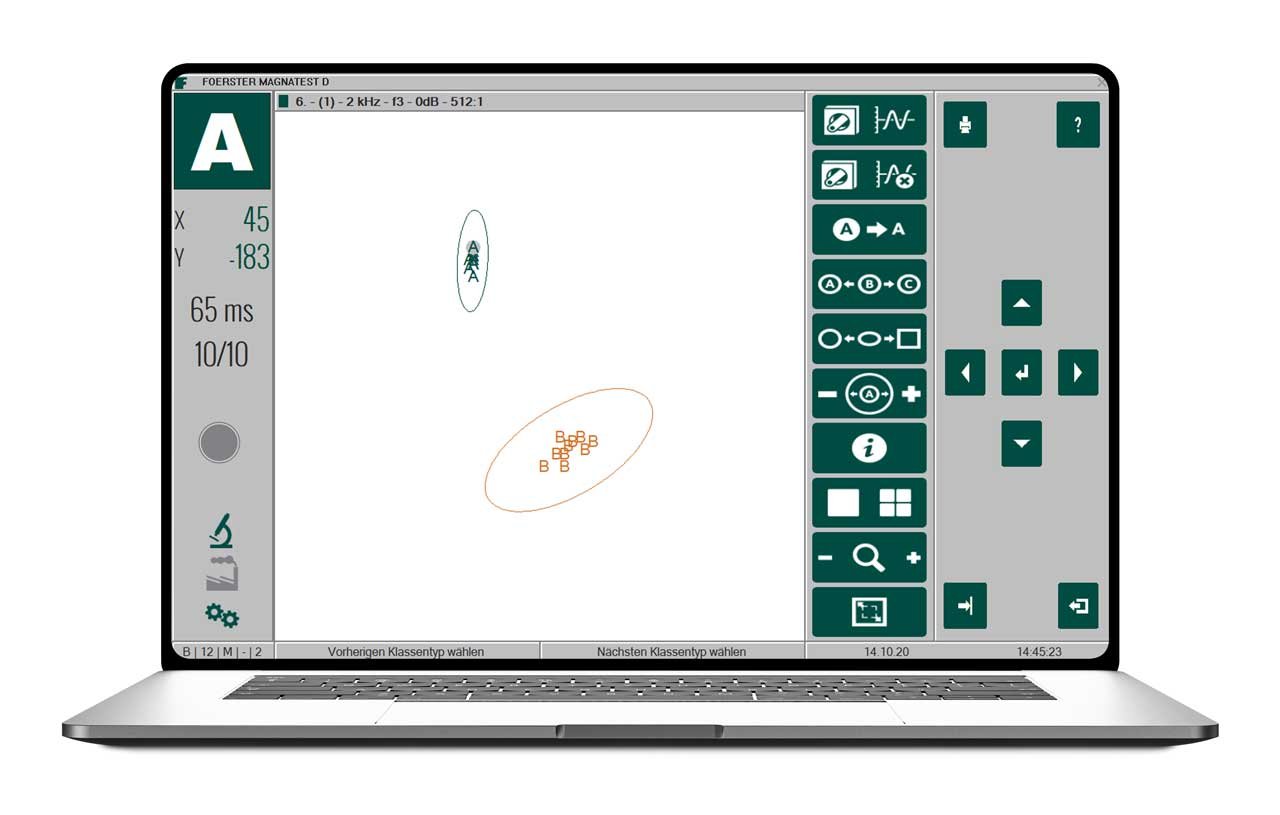

Magnetized components can cause interference signals during eddy current-based crack detection. The result: good parts are incorrectly marked, and pseudo rejects occur, leading to lost profits. If early component demagnetization is carried out early; this issue can be effectively prevented.

In microstructure testing via eddy current, the magnetic properties of a component are primarily checked. Magnetising the components influences these properties. A good part might be marked incorrectly and pseudo rejects can be produced if an inaccurate test result is generated. Therefore we recommend that the components be demagnetized beforehand for a reproducible structure test.

For crack detection with magnetic powder, the components must first be magnetized. In order to avoid the powder from sticking and prevent subsequent processes from being negatively influenced by excessive magnetization, the components must undergo a powerful demagnetization process.

Various machining processes can produce metal chips that adhere to the components or tools. In the further production process these chips can contaminate or even damage the components. To prevent this, it is necessary to demagnetize the components so that the product quality is not endangered.

Fine particles on the material surface as well as residual magnetism can lead to a rough surface and chipping in certain coating processes. In addition, the residual magnetism can have an influence on the coating structure. To ensure a stable coating process, it is therefore necessary to demagnetize the components beforehand.

Nowadays, components that are used in different sensors must comply with certain residual magnetism limits to prevent signal fluctuations. Therefore, there are often corresponding manufacturer standards that specify a certain limit value. By demagnetizing with the ZMAG CM you can comply with these standards and prove them.

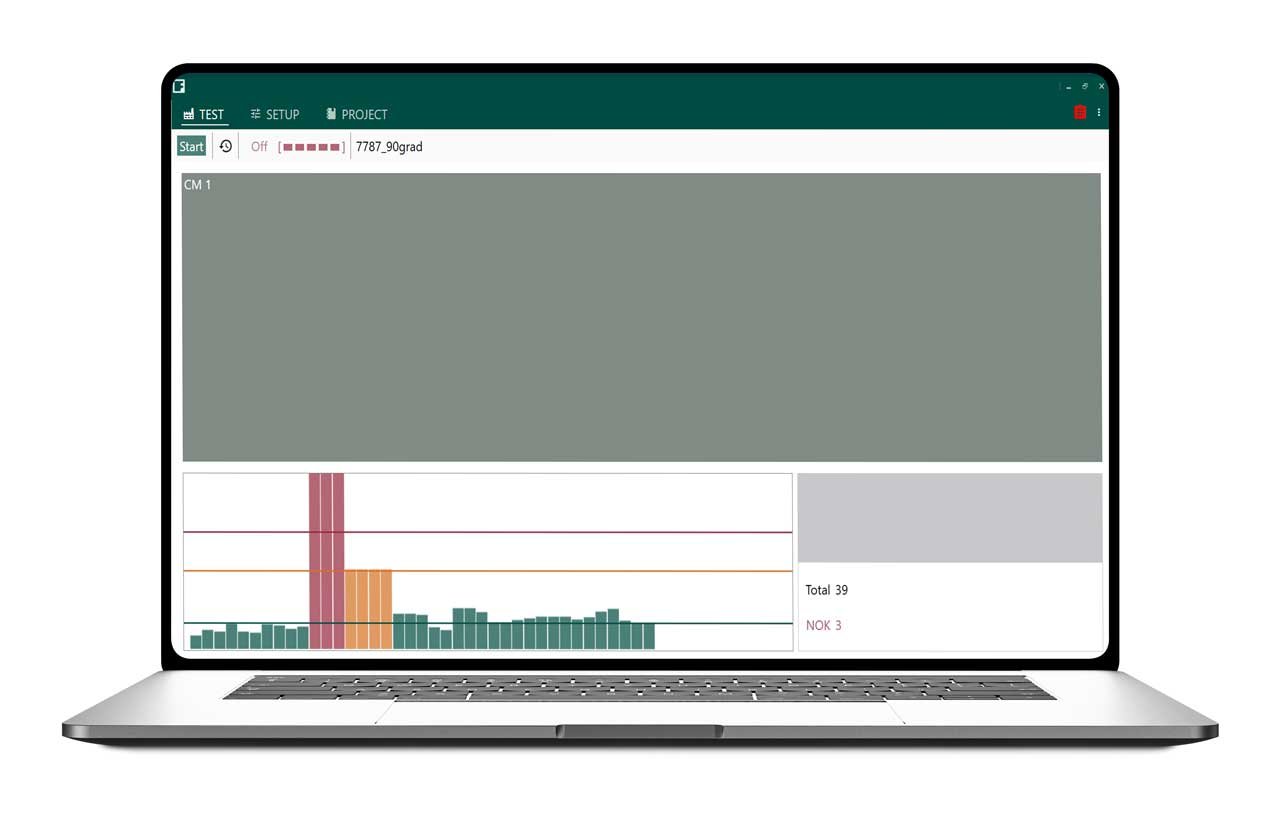

For reproducible crack detection on components, the product solutions of the STATOGRAPH family are available. Due to different production processes, remanence islands can appear in certain areas, frequently on the edges. To ensure that these local magnetizations do not generate interference signals during crack detection, we have the ZMAG CM demagnetization unit in our product portfolio for you. The ZMAG CM demagnetization unit helps you ensure that these local magnetizations do not generate any interference signals during the crack test.

Learn More →

With the testing devices and sensors from the MAGNATEST product family you can reliably test the microstructure and magnetic properties of your components. In this test, it is equally important to counteract interference signals caused by magnetization by means of effective demagnetization. With ZMAG CM you now receive all solutions at once.

Learn More →140 Industry Dr,

Pittsburgh PA,

15275